Performance Trends, Inc.

Producing Quality Computer Tools for Racers and Engine Builders since 1986

Swirl Meter For Flow Bench Testing Cylinder Heads for Intake Air Motion

Theory:

For years engine builders have seen Heads which flow great on the bench get beat on the dyno and the track by heads with less flow. Obviously there is more to cylinder heads than just great flow numbers.

One important aspect for great performing heads is the motion of the incoming fuel/air charge. Generally heads with the correct amount of motion or swirl will perform better because they will burn the fuel/air mixture faster. The Swirl Meter lets you measure intake mixture motion on your flow bench to track differences between just good heads and Great heads. No doubt you've heard about "fast burn" heads or the advantage of dual plug heads which also burn faster. When heads burn faster you gain in 2 ways:

-

The engine will require less spark advance. By firing the mixture closer to TDC there will be less Cylinder Pressure to fight the piston rising to reaching TDC.

-

The burn will be completed sooner after TDC. This creates more cylinder pressure after TDC to push the piston down and make more power.

Both of these effects result in a more efficient engine making more power out of the same amount of air and fuel. In racing you want to maximize the efficiency of the engine because the result is more power. This is especially important in restricted classes of racing where restrictor plates severely limit air and fuel flow.

But, as with anything, you can also have too much swirl, which tends to throw the fuel out on the walls and then down past the rings. Race engines running at high RPM also get motion from squish and quench effects, so they actually may not need extra motion from swirl. We've gotten feedback from head porters who actually like heads with very low amounts of swirl. Others watch the swirl direction and believe that heads where the swirl changes direction as you increase valve lift tend not to run as well as where the swirl direction stays constant. Swirl in gas engines is very much a "black art" and head porters tend to not share their experience from measuring swirl and gaining performance.

However, diesel heads almost always like swirl.

Description:

Our Swirl Meter has steadily been refined. We have options to display updates every half (0.5) second, display averages and updates every 5 or 10 seconds, or show the Maximum, Minimum and Average for the 5 or 10 second period. This is useful to see how stable the swirl was.

Other features of Performance Trends™ Swirl Meter include:

-

Low "flow restriction" design lets you measure swirl at the same time as intake flow (big time savings).

-

Shows direction of swirl, either clockwise or counterclockwise (counterclockwise is indicated as a negative "-" number).

-

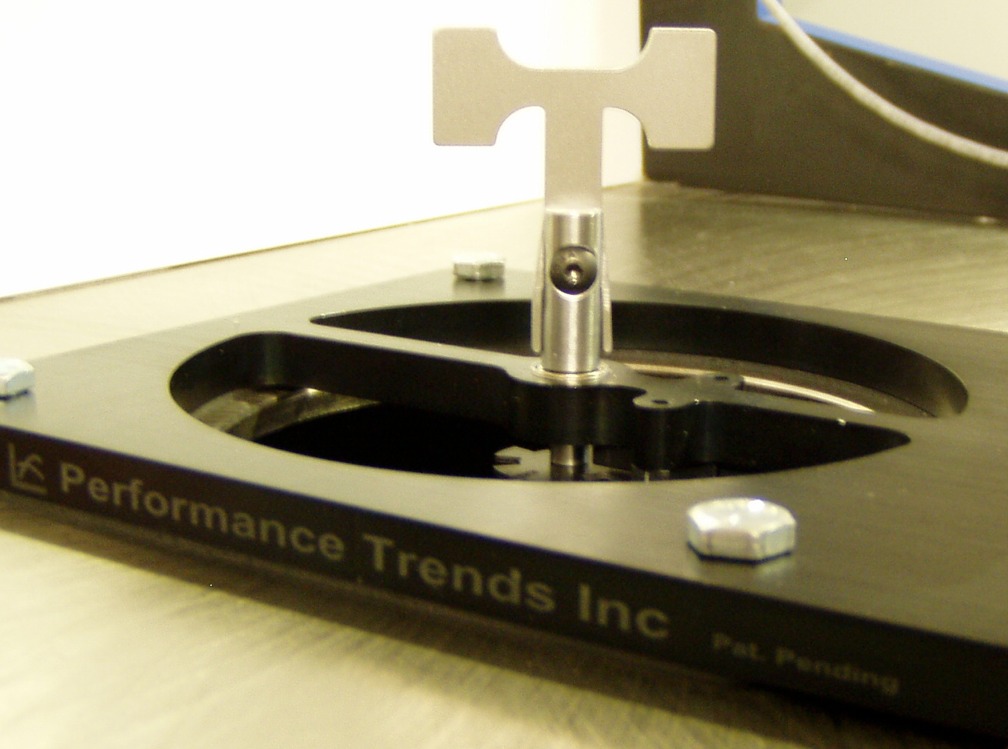

Rugged aluminum and stainless steel design with 20,000 RPM rated bearings designed to hold up in a shop environment.

-

Repeatable, large, backlit, easy-to-read digital readout from -9999 to 9999 RPM with 1 RPM resolution.

-

Optional analog output for SuperFlow's Flow Com (tm).

-

5" mounting holes designed for standard SuperFlow and other manufacturer's flow benches.

-

Low friction bearings provide for more repeatable readings.

-

RPM measurement method eliminates calibration drift of "torque type" swirl measurements.

-

Tumble fixture available for more "in depth" measurements and analysis.

-

Our Port Flow Analyzer to let you easily record Swirl, Swirl Stability, and Tumble directly via USB port, while other flow data is recorded via SuperFlow's FlowCom (tm) electronic flow bench interface or our Black Box II flow bench logger. Port Flow Analyzer Pro or Head Porter versions (not basic) are required to record data.

USB digital communications means VERY precise recording of Average, Maximum, and Minimum Swirl, and no calibration is required. It is basically "plug and play".

for a 5 page brochure more information including details about the menu of options to allow

customizing the USB Swirl Meter's configuration to your particular needs,

and installation tips for various options.

for a 5 page brochure more information including details about the menu of options to allow

customizing the USB Swirl Meter's configuration to your particular needs,

and installation tips for various options.

The Swirl Meter mounts between the bore adapter and the flow bench and records the gross axial, circular motion of intake. The standard 3.75" paddle wheel is designed for bores in the 4 to 4.5 inch range. Custom paddle wheel sizes and designs are available from Performance Trends.

The Swirl Meter does not restrict flow significantly (usually less than 1 CFM at 400 CFM flow). Record the Swirl RPM as you run your flow test and record CFM on the intake port. (There is no use recording swirl when flowing the exhaust port.) Some users make 2 tests, the first without the Swirl Meter to more accurately record CFM without the slight restriction, then another test with the Swirl Meter to record Swirl RPM only. You may want to check the difference in CFM with and without the meter on your heads and decide if 2 separate tests are necessary.

It is important to realize that swirl readings are still relatively new to race engine development and there is no "magic" Swirl RPM to design for. Tests have indicated that you can have too much swirl for some engines, and some successful engine builders actually design for low swirl. Do not simply design for maximum swirl without regard to flow or how the engine behaves on the dyno.

Swirl readings will change with test pressure and CFM flow, distance meter is spaced from the head, clearance between paddle wheel and bore adapter, weather, bearing friction and temperature, etc.) It s important to be repeatable in your testing procedure when checking for minor changes in swirl. When comparing Swirl readings with other engine builders, be sure to consider these differences also. Performance Trends is developing corrections and recommendations as swirl readings become more common.

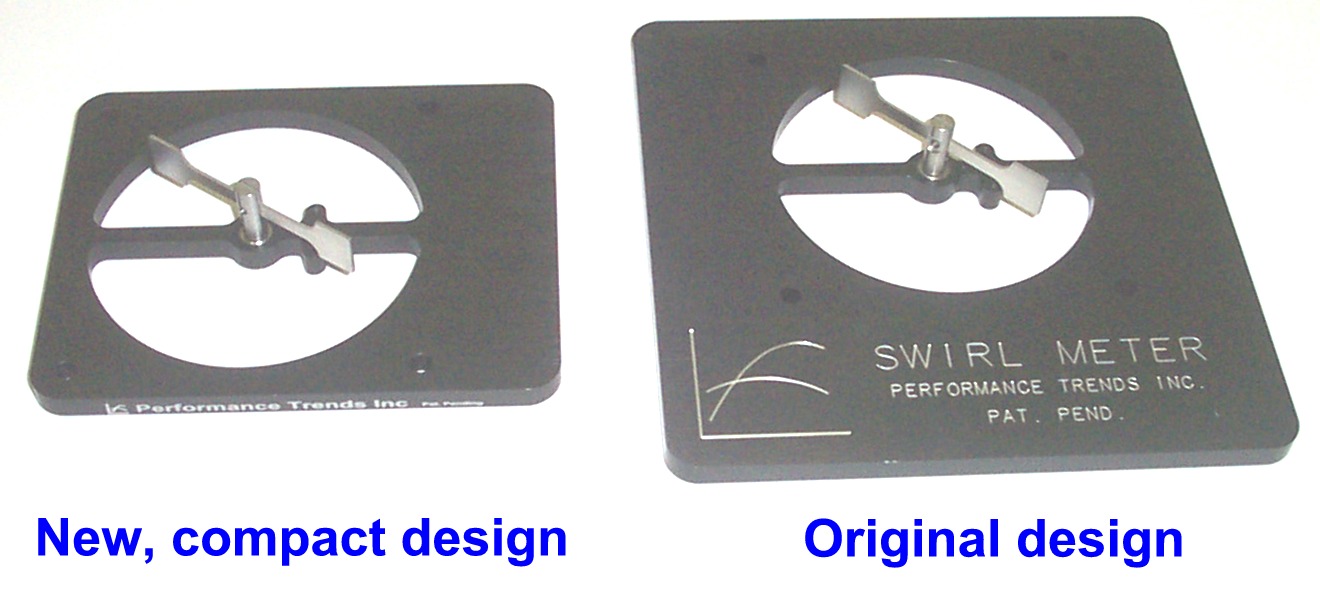

Note: In 2010, we redesigned the plate to a smaller,

more compact design. This can work better for more "cramped"

flow bench installations or on our Tumble Fixture.

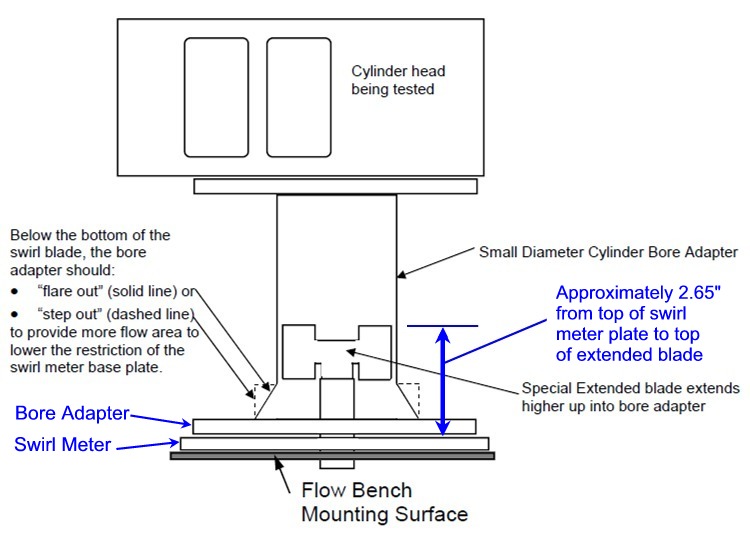

Extended Blade for Small Bores

For very small bores, 2.5" (65mm) or less, the swirl meter bearing and sensor support arm can be a flow restriction. For these bore sizes, we offer the extended blade option as pictured below. User must supply the proper bore adapter design to reduce flow restriction, as pictured below.

![]() for prices of various options.

for prices of various options.

To Order:

Call 248-473-9230. Visa and Mastercard accepted.

Electronics like Swirl Meter have a limited 1 year warranty.